N vs NU Bearing Types

By Cory Mittleider on 2/8/2026

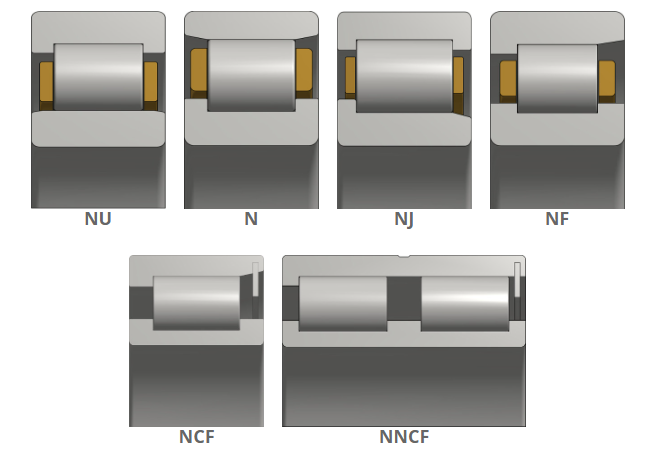

Variety of CRB types available

In the application of High-Speed Shaft (HSS) and High-Speed Intermediate Shaft (HSIS or IMS) on wind turbine gearboxes sometimes you may be asked to choose between N or NU type bearings.

While they look different during assembly, these two bearing types are functionally similar. Understanding their design can help you evaluate a possible substitution for your repair needs.

Same Performance, Different Architecture

Both N and NU bearings are designed for heavy radial loads and because of their “floating” design, they allow for axial expansion of the shaft with temperature changes that occur during operation.

Bidirectional Separation: Both types are separable in both directions. Where N allows for full separation of the outer ring, NU allows for full separation of the inner ring. See the animations in figures 1 and 2.

Non-Locating: Neither of these bearing designs can carry a thrust load and must always be paired with locating bearings in a design to handle the axial forces.

In Application: Wind Turbine Gearboxes

There are 2 very common HSS configurations where these bearings are utilized.

1.The QJ Setup: Two N or NU bearings are used to support the high radial loads applied while a 4-point angular contact ball bearing (part number starts with “QJ”) is used to manage axial loads in both directions as seen in figure 3.

Figure 3: Common HSS setup with 2x N/NU CRB’s + QJ bearing

2. The TRB Setup: A single N or NU bearing is used on one side of the shaft for high radial loads with a pair of Tapered Roller Bearings (TRBs) on the other side of the shaft which can carry both high radial load and bidirectional axial loads as seen in figure 4.

Figure 4: Common HSS setup with 1x N/NU CRB + TRB set

In the field

While a gearbox may have originally been fitted with an N type bearing there are a couple of reasons we may offer an NU alternative.

Availability:

NU bearings are much more common than N type bearings. We do typically stock some of the N bearings found in wind turbine gearboxes, but with the same bearing size and features often used in other gearboxes we often have higher quanitites and/or shorter lead times on NU type bearings.

Ease of assembly:

• The N type challenge: the cage and rollers are fixed to the inner ring. When installing the inner ring to the shaft these items are also installed and exposed. Navigating the heavy, assembled shaft back into a cramped gearbox housing without nicking or damaging the rollers is a high-risk task. See animation in figure 5.

•The NU type solution: the cage and rollers stay protected inside the outer ring which is seated independently in the housing. You only need to install the light, inner ring of the NU style bearing on the shaft and because of the smaller overall size this will ease re-insertion of the HSS into the gearbox. See animation in figure 6.

Figure 5: Installation of a HSS with N type bearing

Figure 6: Installation of a HSS with NU type bearing

Conclusions:

Because N and NU bearings share the same dimensions, load ratings, and “floating” capabilities, these bearings can often be treated as interchangeable. In fact, some customers have specifically asked us to provide NU type bearings to simplify uptower repairs.

Do you have questions about bearings for your turbine to speed up repairs, increase uptime, or both? Contact Us today.

Additional resources: